detailed information

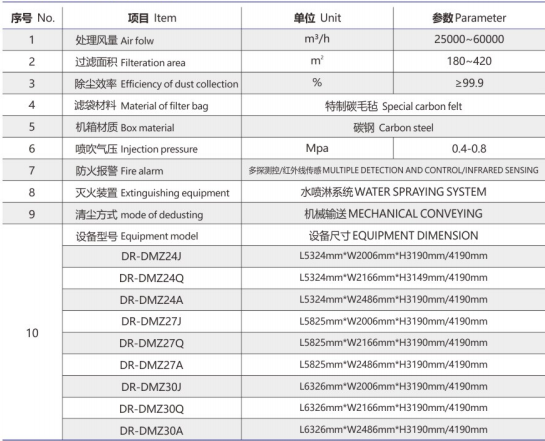

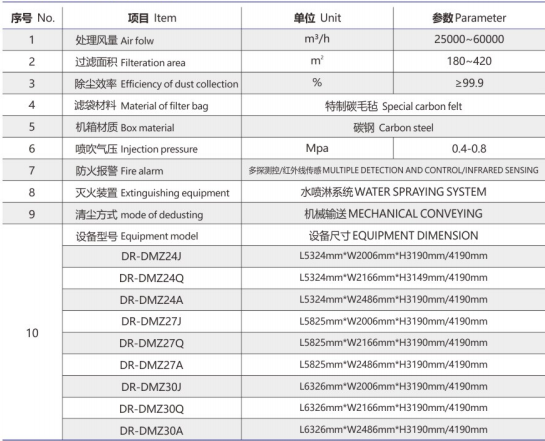

technical parameter:

The dust-containing gas is conveyed by the fan into the dust collector. The large particles of dust are separated and fall directly into the ash hopper. The remaining light dust is evenly distributed with the airflow through the shunt baffle, and then filtered by a high-density filter bag. The filtered clean gas Dust into the atmosphere from the exhaust hood; as the filtering conditions progress, dust will accumulate on the surface of the filter bag, when the dust accumulates to a certain amount, the dust will fall off automatically, and the dust on the remaining filter bag will be discharged by the air pressure pulse cleaning device Cleaning, this cleaning device can be set: 1. Automatic cleaning (when the production line stops or the gap is stopped, the air pressure pulse cleaning device will automatically open for cleaning, once the production line starts, the device will automatically close at the same time); 2. On-line cleaning: the production line is in During normal production, it can also be cleaned regularly according to resistance needs, and at the same time, screw conveyor dust removal. 3. Manually control cleaning. Turn on the air source to clean up according to the set program, and shake off the dust on the filter bag. The dust falling into the ash hopper is discharged by the conveying system. Normally stop dust to discharge, you can also customize the dust collector to discharge dust automatically when the production line is turned on according to the customer's requirements, or when multiple dust collectors are turned on, the dust collector can be used to discharge the dust and air flow to convey the concentrated dust package.

Low energy consumption

Large air volume

Less consumables

Online dust removal

high efficiency

Keep safe

Worry free

technical parameter: